Dual-plate Surface Processor

Purposes: the cloth after PU of PVC, TUP oil or water-based resin paint, foam, high solid by gravure drum transfer to the fabric surface, breathable, water vapor permeability of the surface of high-quality printing and processing; widely used in knitted, woven, cotton, chemical fiber, synthetic leather, woven fabrics, microfiber and other fabrics series, printing Figure. The text is clearly visible, rich layers, stereoscopic maximize value-added products and the appearance of style elegance, Fashion.

Product introduction:

One, the basic specification, and mechanical

1st printing processor

Drying oven

Section II printing processor

Network with the correction system

Cooling, the volume pick put down

Temperature: 80 ℃ -180 ℃

Main power: inverter motor drive system and pneumatic tension linked to the control system

Mechanical speed :5-40M / min

Purposes: the cloth after PU of PVC, TUP oil or water-based resin paint, foam, high solid by gravure

Drum transfer to the fabric surface, breathable, water vapor permeability of the surface of high-quality printing and processing; widely used in

Knitted, woven, cotton, chemical fiber, synthetic leather, woven fabrics, microfiber and other fabrics series, printing Figure

The text is clearly visible, rich layers, stereoscopic maximize value-added products and the appearance of style elegance

, Fashion.

The type of fabric: knitted, woven, cotton, chemical fiber, synthetic leather and a variety of fabrics

Heating mode of heat sources: steam or hot kerosene

1st printing processor

Drying oven

Section II printing processor

Network with the correction system

Cooling, the volume pick put down

Temperature: 80 ℃ -180 ℃

Main power: inverter motor drive system and pneumatic tension linked to the control system

Mechanical speed :5-40M / min

Purposes: the cloth after PU of PVC, TUP oil or water-based resin paint, foam, high solid by gravure

Drum transfer to the fabric surface, breathable, water vapor permeability of the surface of high-quality printing and processing; widely used in

Knitted, woven, cotton, chemical fiber, synthetic leather, woven fabrics, microfiber and other fabrics series, printing Figure

The text is clearly visible, rich layers, stereoscopic maximize value-added products and the appearance of style elegance

, Fashion.

The type of fabric: knitted, woven, cotton, chemical fiber, synthetic leather and a variety of fabrics

Heating mode of heat sources: steam or hot kerosene

technical parameter:

Second, Type: gravure roll coating type

Purposes: cloth, leather class surface, PU glue, PVC glue, colored plastic, water-based glue

Range of roll coating: Viscosity: 1800CPS-2200CPS speed :5-40M / min.

Specialties:

The impression cylinder and the printing cylinder gap precision fine-tune the worm gear box control (± 0.2), the coating weight is stable

Step uniform;

The scraper string dynamic design independent electric transmission and main drive separation;

Between the blade and the printing cylinder can be adjusted to meet different printing roller diameter.

Third, the drying oven

Features:

Independent drying system design, the nozzle air flow uniformity;

Oven on both sides of a specially designed magnetic door switch, easy to hand-wear materials and cleaning and maintenance;

High temperature Teflon with a double transfer, ensure that the fabric printing, tension-free stereotypes drying;

PID automatic temperature control system and a new and efficient closure of the entire oven;

Fourth, the network with correcting system

Features:

Specially designed to ensure that the conveyor belt automatically correcting

Transmission network with fault alarm, the use of stable, reliable

Two roller water cycle cooling

, Put off the device / take-up rewinding

Calender processor

Main purposes:

This machine is mainly applicable to the processing of cotton, chemical fiber, linen cloth, wool and blended fabrics, surface processing, change

Good fabric feel, softness and smoothness, to enhance the fabric surface grade to reach breathable anti-velvet, hand

Especially good sense and special light.

Purposes: cloth, leather class surface, PU glue, PVC glue, colored plastic, water-based glue

Range of roll coating: Viscosity: 1800CPS-2200CPS speed :5-40M / min.

Specialties:

The impression cylinder and the printing cylinder gap precision fine-tune the worm gear box control (± 0.2), the coating weight is stable

Step uniform;

The scraper string dynamic design independent electric transmission and main drive separation;

Between the blade and the printing cylinder can be adjusted to meet different printing roller diameter.

Third, the drying oven

Features:

Independent drying system design, the nozzle air flow uniformity;

Oven on both sides of a specially designed magnetic door switch, easy to hand-wear materials and cleaning and maintenance;

High temperature Teflon with a double transfer, ensure that the fabric printing, tension-free stereotypes drying;

PID automatic temperature control system and a new and efficient closure of the entire oven;

Fourth, the network with correcting system

Features:

Specially designed to ensure that the conveyor belt automatically correcting

Transmission network with fault alarm, the use of stable, reliable

Two roller water cycle cooling

, Put off the device / take-up rewinding

Calender processor

Main purposes:

This machine is mainly applicable to the processing of cotton, chemical fiber, linen cloth, wool and blended fabrics, surface processing, change

Good fabric feel, softness and smoothness, to enhance the fabric surface grade to reach breathable anti-velvet, hand

Especially good sense and special light.

Sample display:

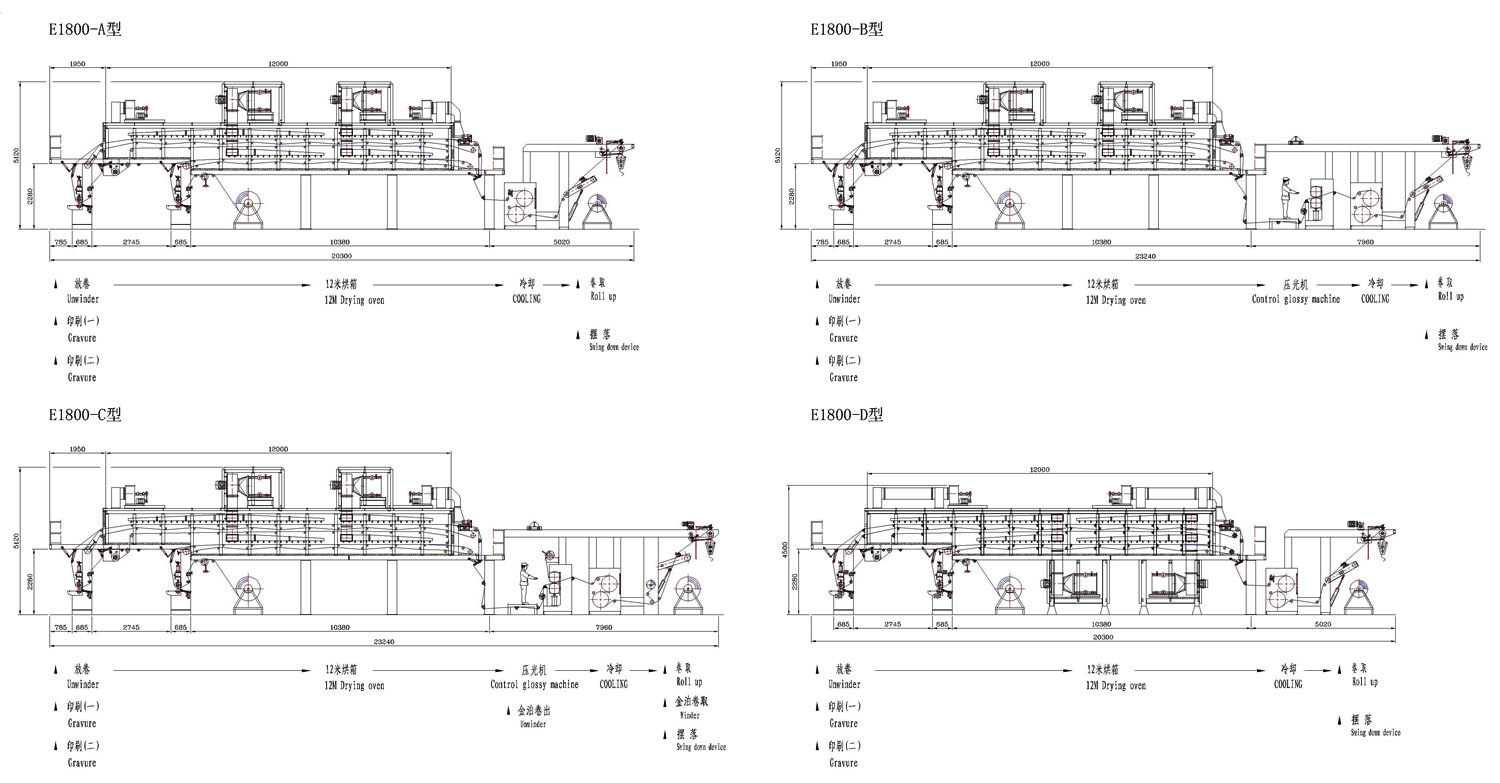

Composition figure

Video:

Recommended products

more+

Hot news

more+

The use and classification of rubber machine

2022-06-30

86-595-85730606

86-595-85730606

閩公網(wǎng)安備35058202001412

閩公網(wǎng)安備35058202001412

86-595-85730606

86-595-85730606