Cloth Coating Machine

Uses: cloth after PU, PVC, AC and other oil-based or water-based glue coating on the surface, form the fabric waterproof, crack prevention yarn, waterproof, breathable and flame retardant, can be widely used for umbrellas, tents, handbags, raincoat, windbreaker, snow, and many other leisure activities equipment, household items, but also significantly increase the added value of the fabric.

Product introduction:

First, the basic specification, and machinery

Bolts of cloth warm-up ironing processing

Glue coating machine

Drying oven

Cooling, curled or put off the

Temperature: 60 ℃ -180 ℃

Main power: inverter motor drive system and the constant tension control system

Mechanical speed: the fastest per minute 87M

Uses: cloth after PU, PVC, AC and other oil-based or water-based glue coating on the surface, form the fabric waterproof, crack prevention yarn, waterproof, breathable and flame retardant, can be widely used for umbrellas, tents, handbags, raincoat, windbreaker, snow, and many other leisure activities equipment, household items, but also significantly increase the added value of the fabric.

The type of fabric: plain weave and the type of fabric.

Heating mode of heat sources: steam or hot kerosene

Bolts of cloth warm-up ironing processing

Glue coating machine

Drying oven

Cooling, curled or put off the

Temperature: 60 ℃ -180 ℃

Main power: inverter motor drive system and the constant tension control system

Mechanical speed: the fastest per minute 87M

Uses: cloth after PU, PVC, AC and other oil-based or water-based glue coating on the surface, form the fabric waterproof, crack prevention yarn, waterproof, breathable and flame retardant, can be widely used for umbrellas, tents, handbags, raincoat, windbreaker, snow, and many other leisure activities equipment, household items, but also significantly increase the added value of the fabric.

The type of fabric: plain weave and the type of fabric.

Heating mode of heat sources: steam or hot kerosene

technical parameter:

Two types: scraper

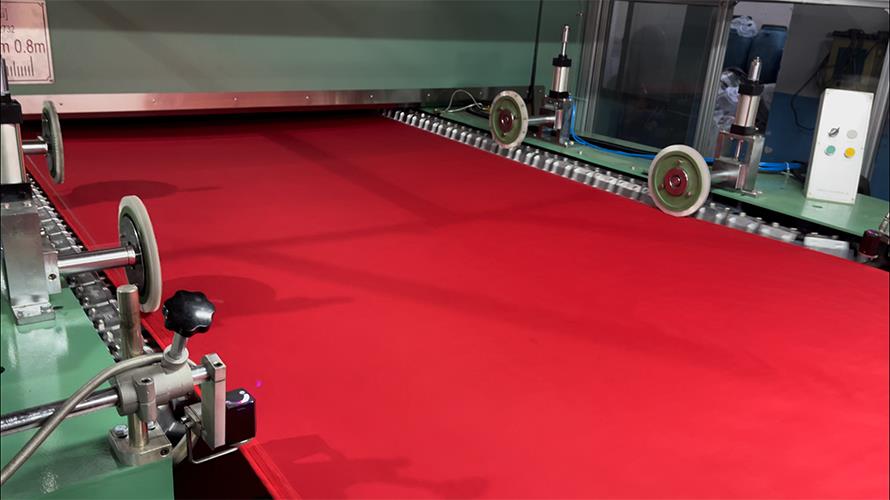

Purposes: the surface of the cloth, PU glue, acrylic plastic, rubber, PVC plastic, colored plastic, water-based glue, waterproof glue, coating processing.

Coating: Viscosity: 2000CPS-50000CPS

Speed :5-100M / min.

Coating weight: 15g / ㎡-100g m

Features: retaining the plastic sheet automatic tracking devices, easy to use, save on labor.

Speed adjustable tension, and six-phase scraping force angle in order to control the coating range.

Can choose from three coating method, coating stability.

New constant tension automatic control, stable and uniform coating weight.

Three warm-up ironing wheels

Fourth, the drying oven

Features: hot air circulation, specially designed nozzle air flow evenly

Can coating weight adjustment fresh with the internal circulating air mixing to ensure that the box safe concentration

Device exhaust air volume control system to maintain the mechanical operation of the security exhaust volume to prevent the oven gas explosion.

Cooling wheel, tank ring

Six out of the cloth material storage device

Coiling rewinding

, Coating into the pin tenter device

Purposes: the surface of the cloth, PU glue, acrylic plastic, rubber, PVC plastic, colored plastic, water-based glue, waterproof glue, coating processing.

Coating: Viscosity: 2000CPS-50000CPS

Speed :5-100M / min.

Coating weight: 15g / ㎡-100g m

Features: retaining the plastic sheet automatic tracking devices, easy to use, save on labor.

Speed adjustable tension, and six-phase scraping force angle in order to control the coating range.

Can choose from three coating method, coating stability.

New constant tension automatic control, stable and uniform coating weight.

Three warm-up ironing wheels

Fourth, the drying oven

Features: hot air circulation, specially designed nozzle air flow evenly

Can coating weight adjustment fresh with the internal circulating air mixing to ensure that the box safe concentration

Device exhaust air volume control system to maintain the mechanical operation of the security exhaust volume to prevent the oven gas explosion.

Cooling wheel, tank ring

Six out of the cloth material storage device

Coiling rewinding

, Coating into the pin tenter device

Sample display:

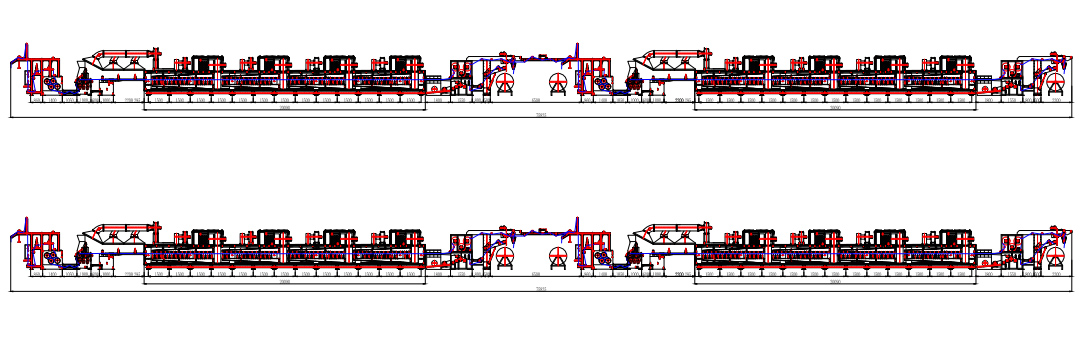

Composition figure

Video:

Recommended products

more+

Hot news

more+

The use and classification of rubber machine

2022-06-30

86-595-85730606

86-595-85730606

閩公網(wǎng)安備35058202001412

閩公網(wǎng)安備35058202001412

86-595-85730606

86-595-85730606